Fiber Optics

fiber optic hand woven fabrics

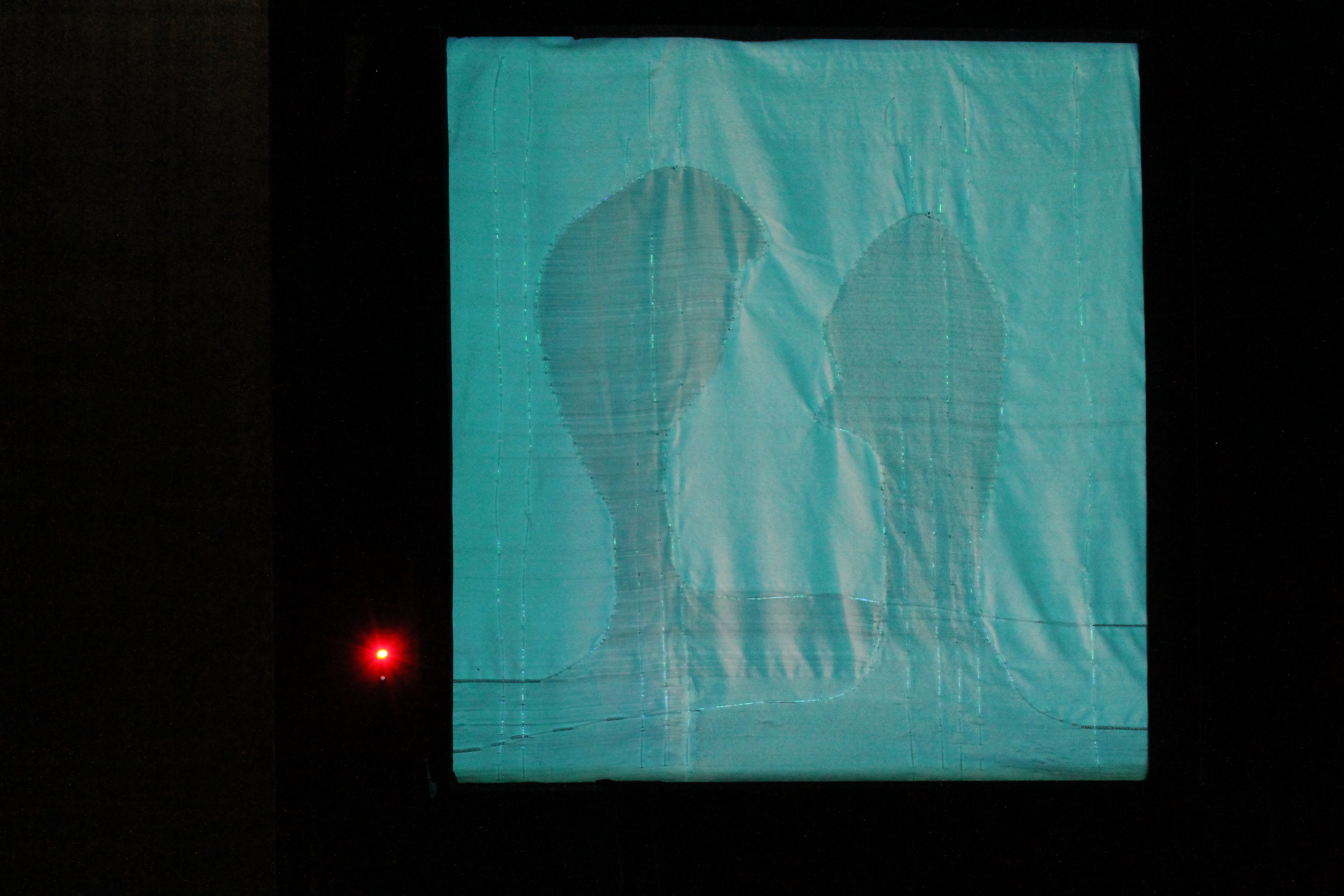

these hand woven pieces were created on an 8 harness dobby loom threaded with 840 end of white cotton warp. the warp is treated with fluorescent whitening agents (FWA) which react under UV light by glowing blue. untreated cotton yarns were used as weft as well as other FWA yarns to create designs that were dynamic beyond the LED interactivity.

two different materials with fiber optic properties were used in conjunction with LED lights to create luminescent textiles.

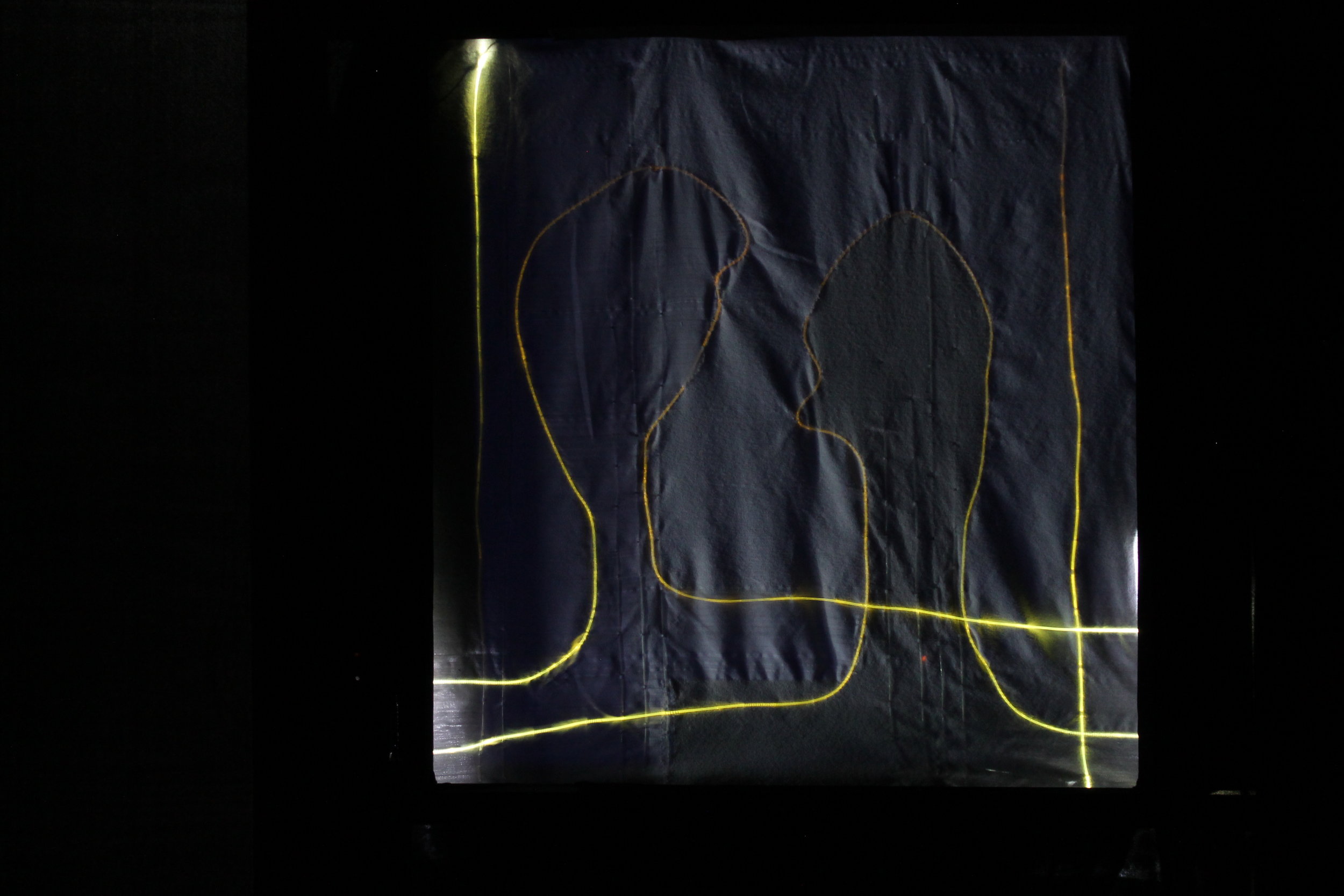

first: fiber optic filaments of 0.5mm diameter were bundled in groups of 5 at different lengths to be used to create a woven image.

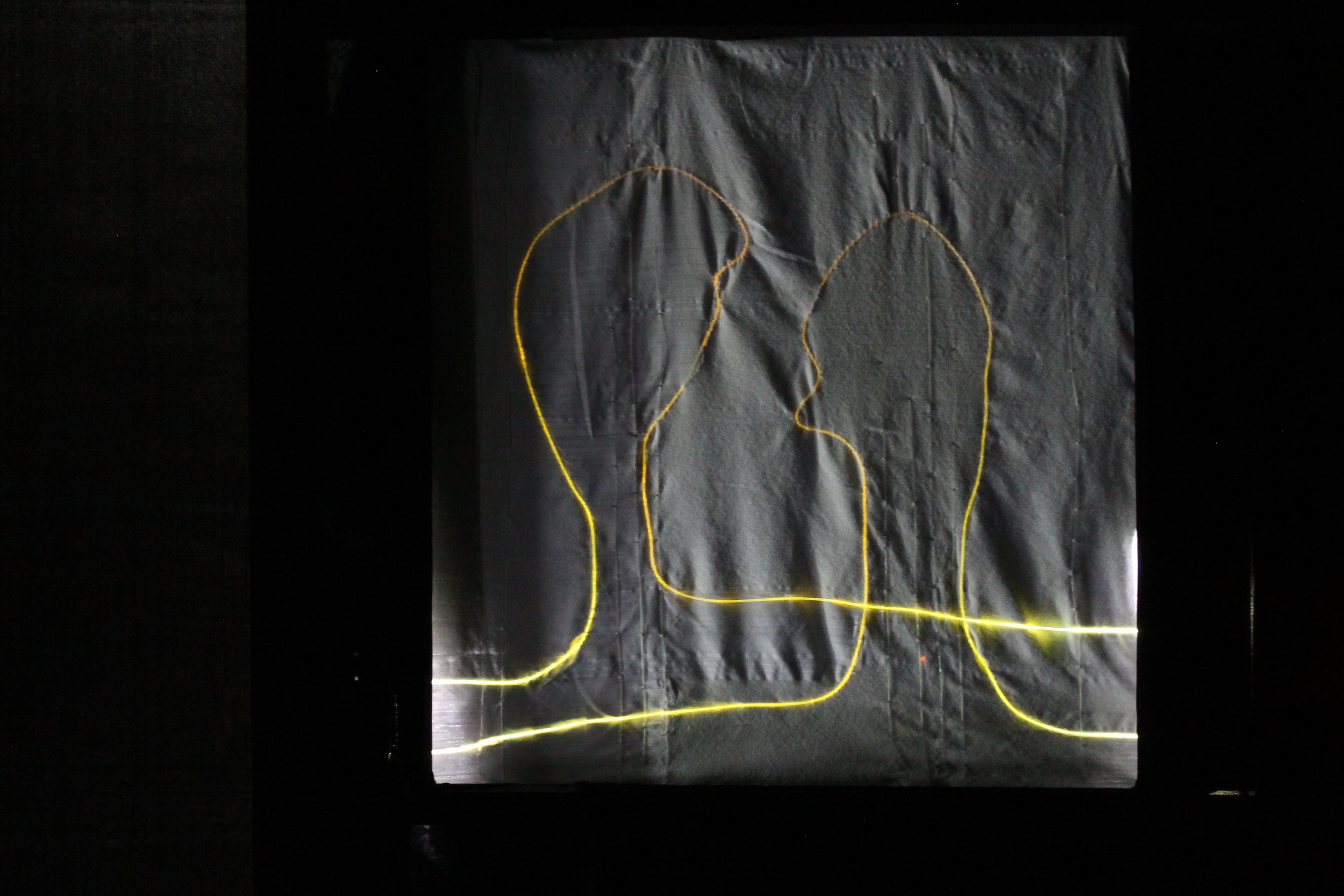

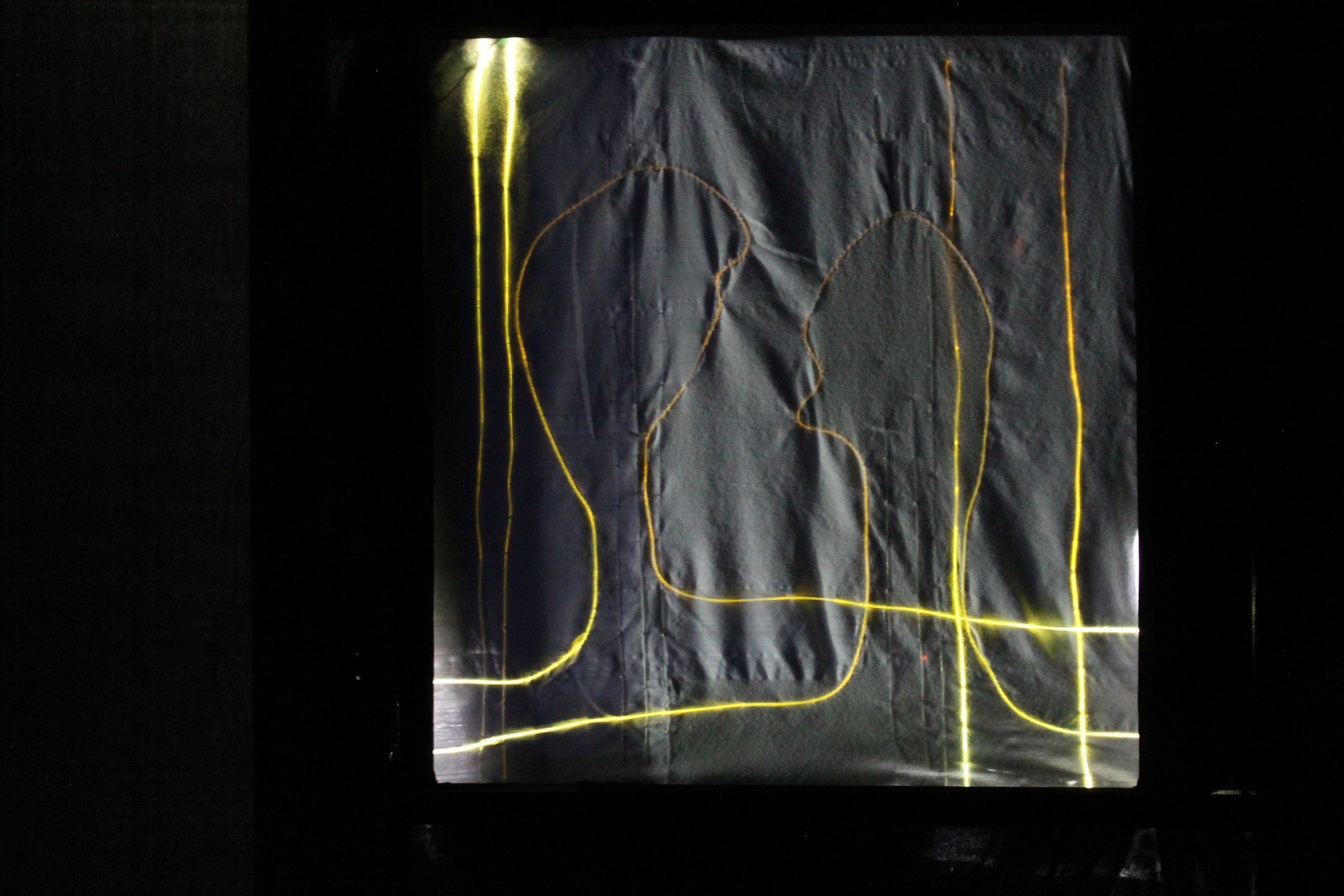

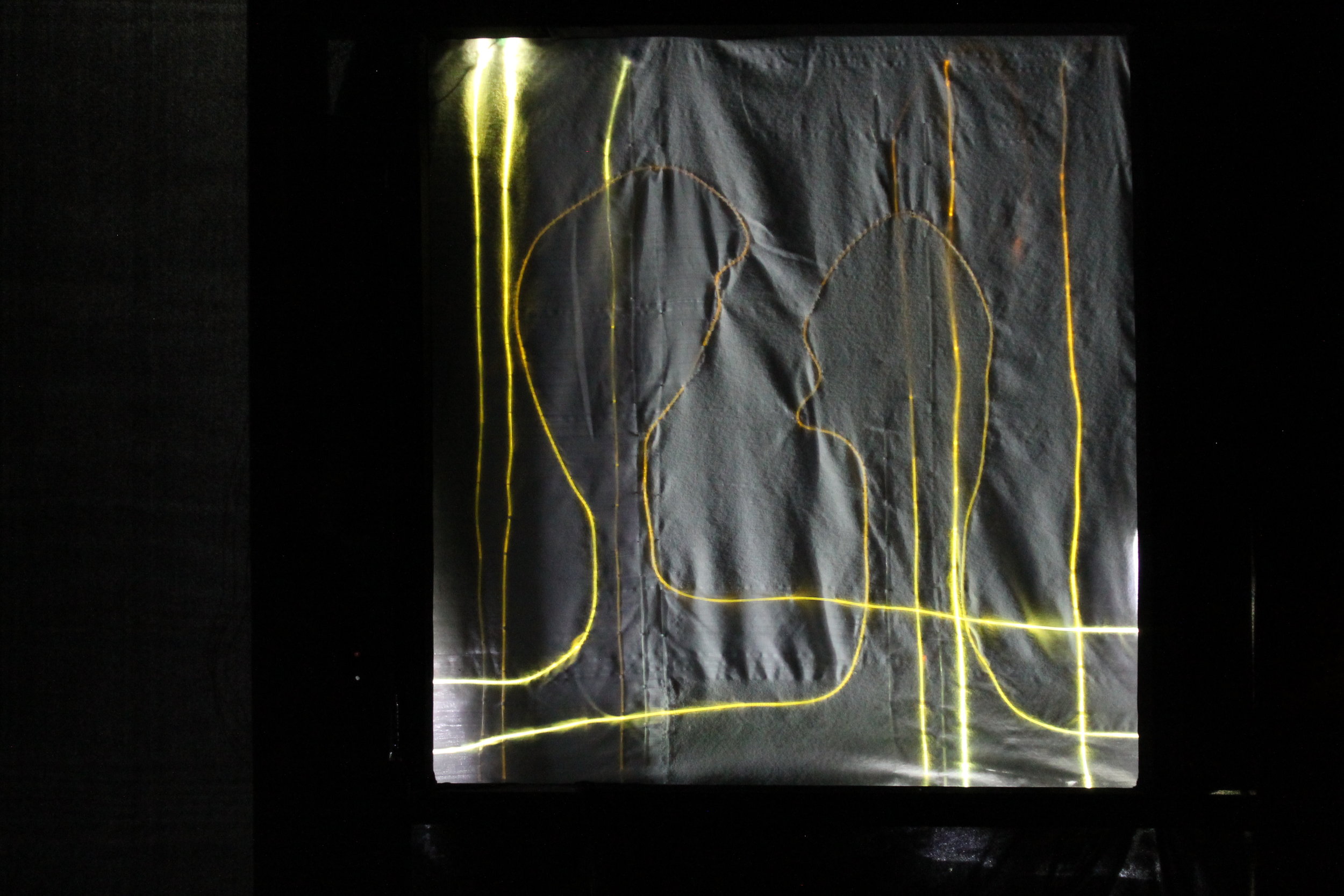

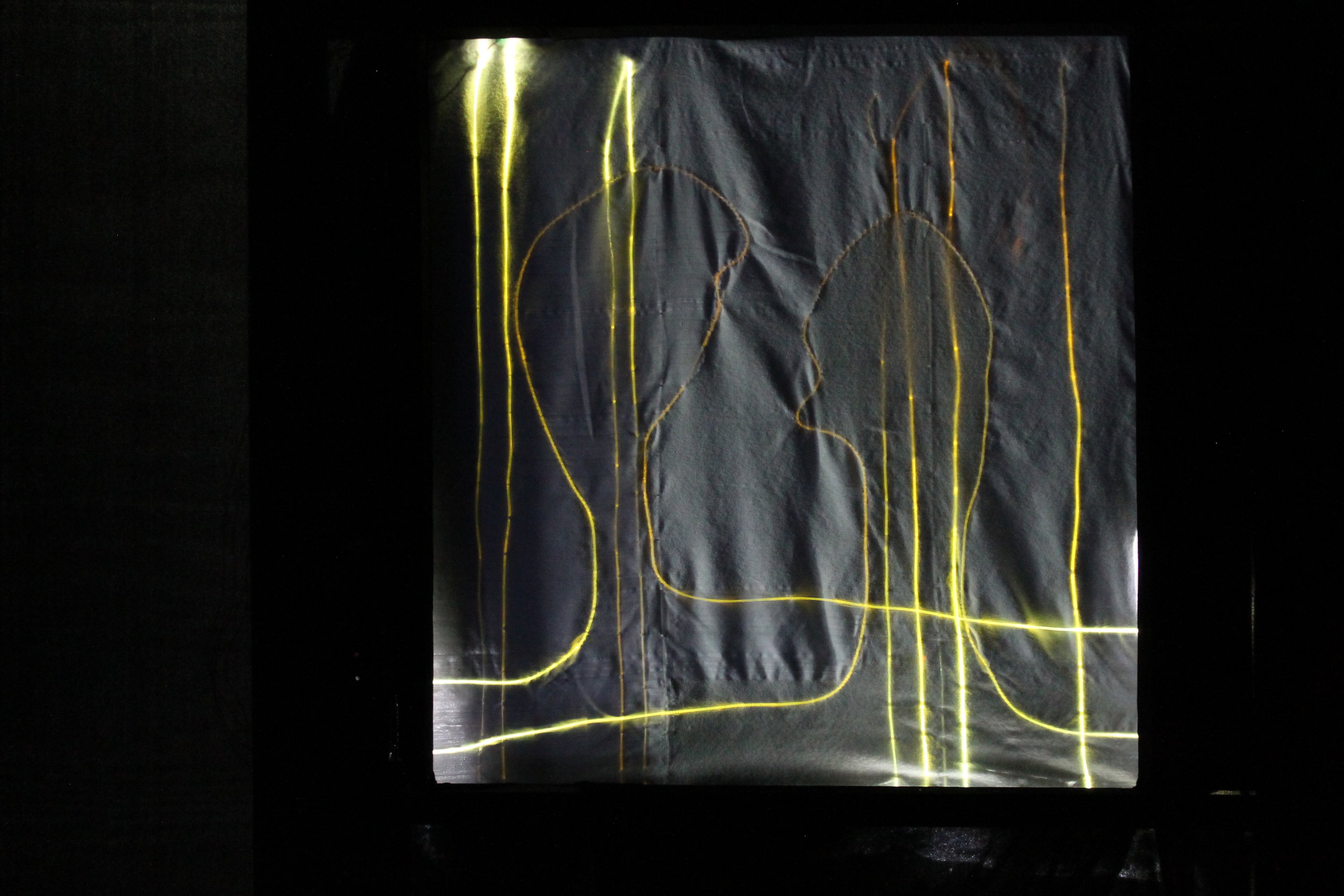

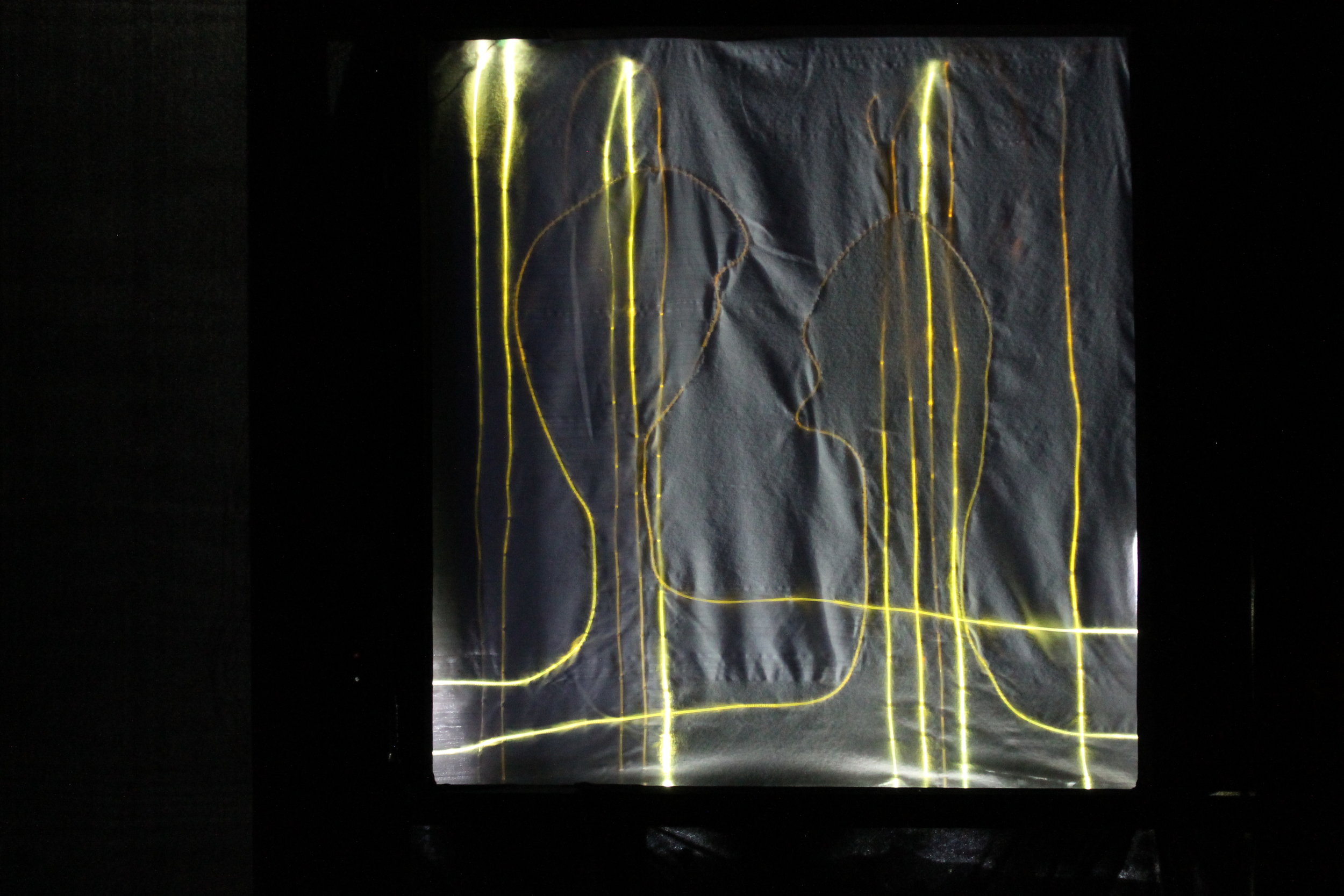

second: medical grade polyurethane tubing was used in both the warp and weft of a piece to "draw" in a woven image.

the FWA yarns glow blue under UV light. FWA cotton in used in apparel practices to make white garments look whiter. These pieces use the differential reactivity of yarns with and with out FWA to create designs.

A cartoon was used to to create the design of the face and define how long the fiber optic filaments should be. final woven piece off loom. next add LEDs.

once all of the fiber optic filament bundles were connected to the LED strand, my collaborator Alex Marino, used an Arduino to program a UV light sensor to trigger a the LED strand to turn on. after that was successfully programmed, Alex and I worked to create a dynamic light show from the movement and pattern of LED illumination.

EXTRA FUN: the LED strand is an RGB LED chain, the intention of the piece was to use all wavelengths of light in equal power ratios to make the resultant light appear white, as this was intended to be a white on white collection only enhanced by the presence of light. when that trial was run, it was discovered that by placing the fiber optic filaments in direct contact with the LED surface, the light that was transmitted along the filament was a color due to the split diodes of the LED neopixels. the colorful result was more engaging and pushed the collection to new places.

this amazing polyurethane tubing when exposed to a super bright LED transmits lights along its length (up to 3 feet) from white to a reddish orange at the end. so, as the light travels the wavelength increases. another happy accidental discovery that allowed for fantastic developments within the thesis collection.

rather than attempting to incorporate the medical grade tubing into the warping of the piece (through the heddles and reed), it was placed in the warp and the weft directions.

additionally, two different cotton yarns were used. one treated with Fluorescent Whiteners and the other not, so under UV light another level of design development was revealed.